Industrial Design Capstone

Goal

Create high quality ceramic home-good products using plaster mold making and slip casting processes.

Problem Statement

Ceramic travel mugs currently available on the market use either a plastic or silicone lid. These materials provide a lackluster user experience when drinking from them. I aim to create an insulated portable vessel that a has a ceramic lid for the user’s lips to drink from.

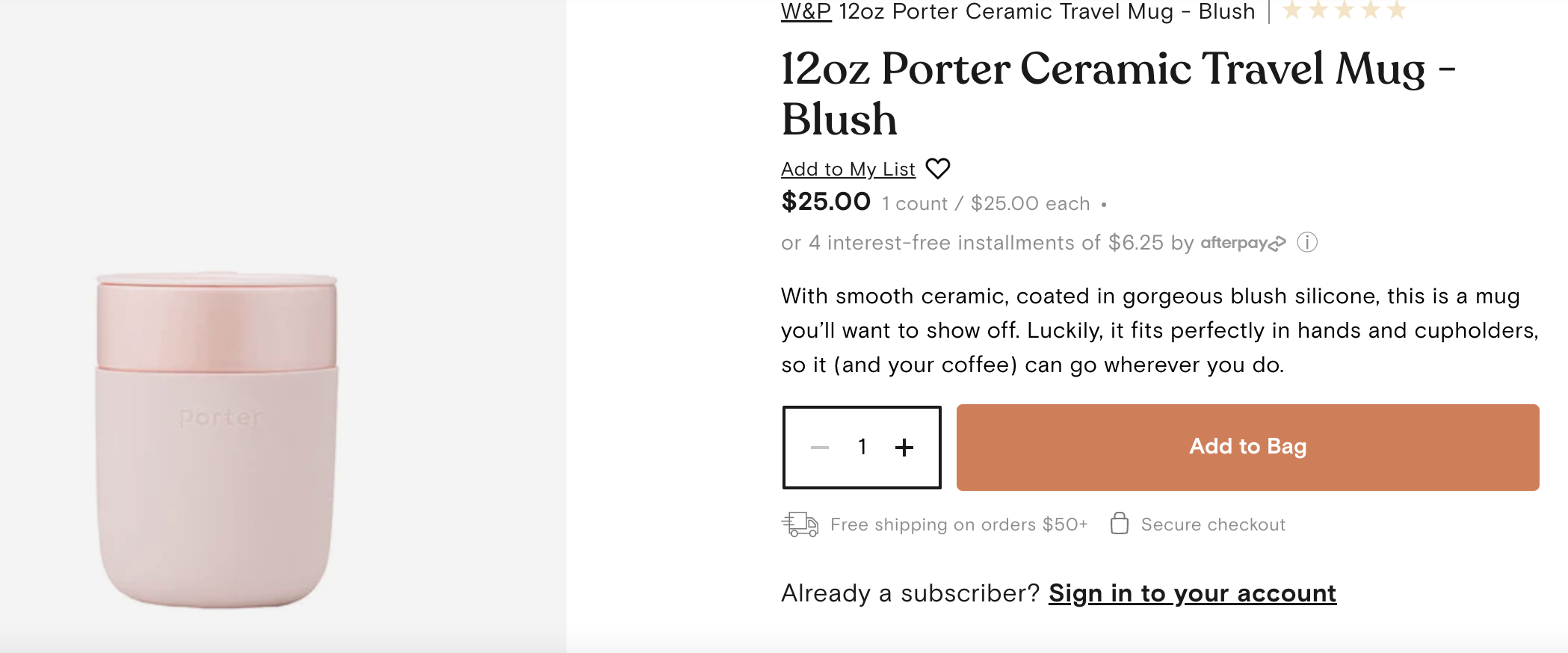

Currently Available

Plastic lid

Coated in silicone, hiding the ceramic body, I want my design to be true to the material

Silicone lid, poor user experience and difficult to wash

Not insulated

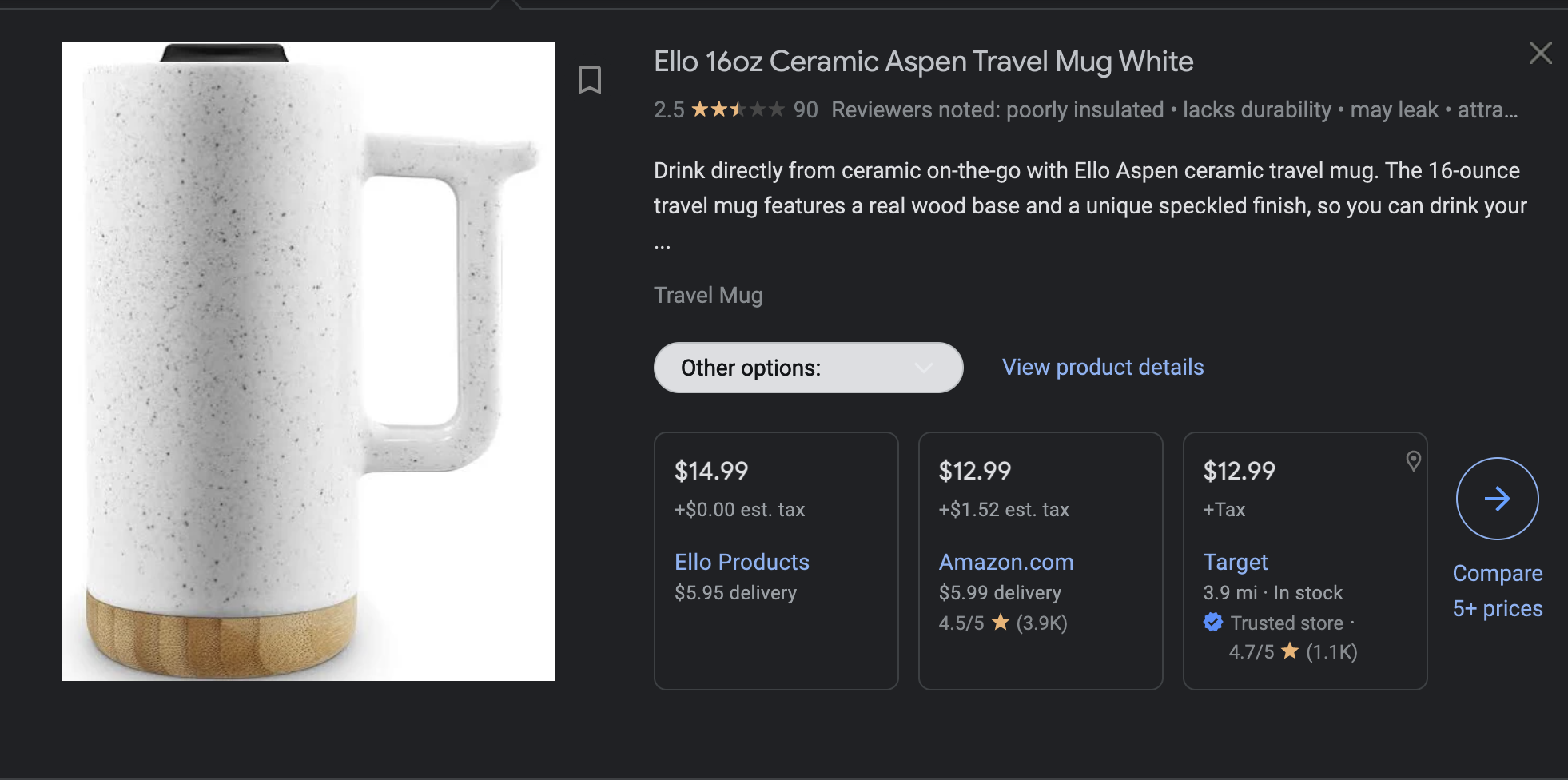

Plastic lid

Added handle takes place of insulated walls

Concept Iteration 1

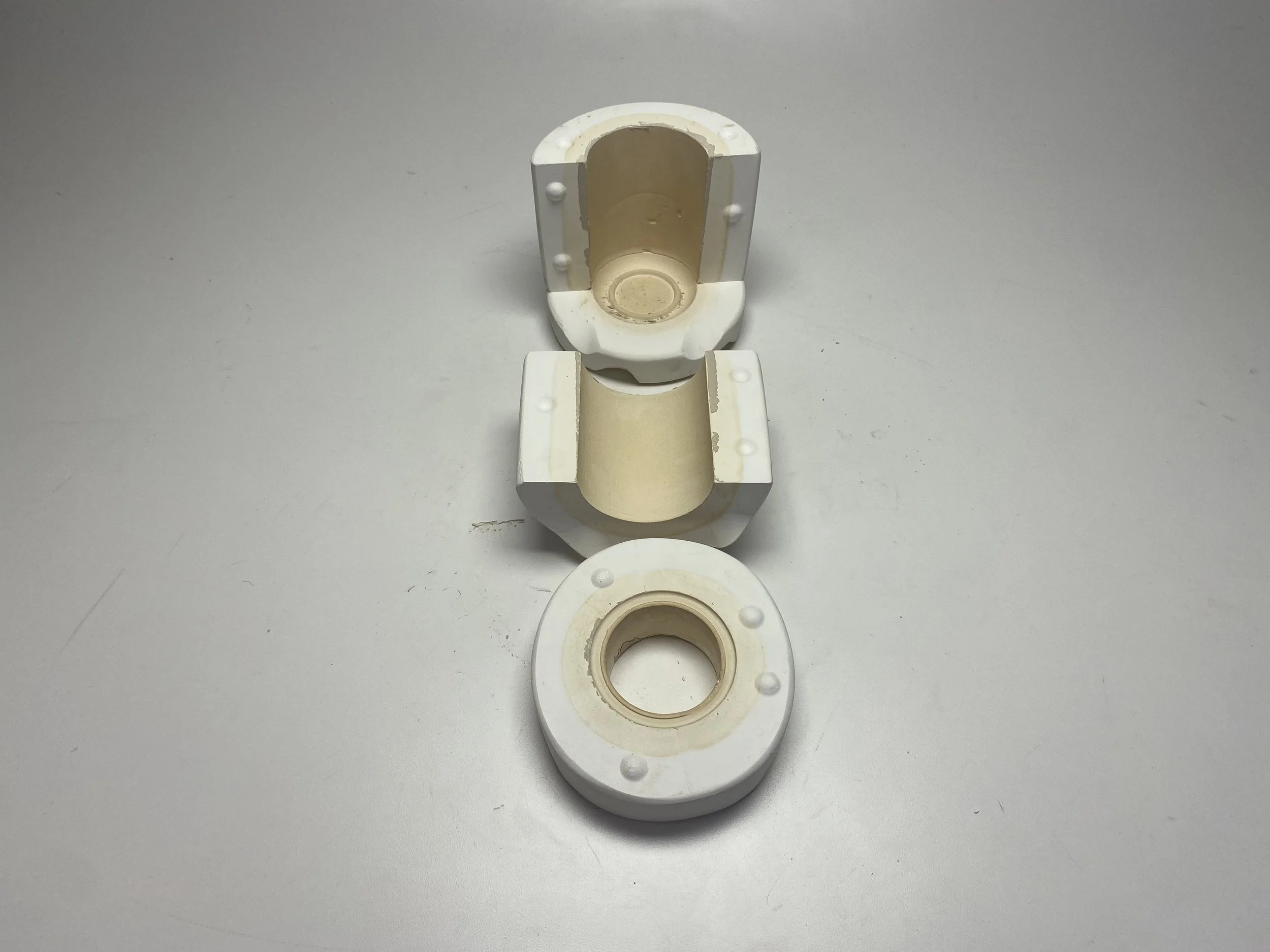

Mold Systems

Lid Mold

Interior Wall Mold

Exterior Wall Mold

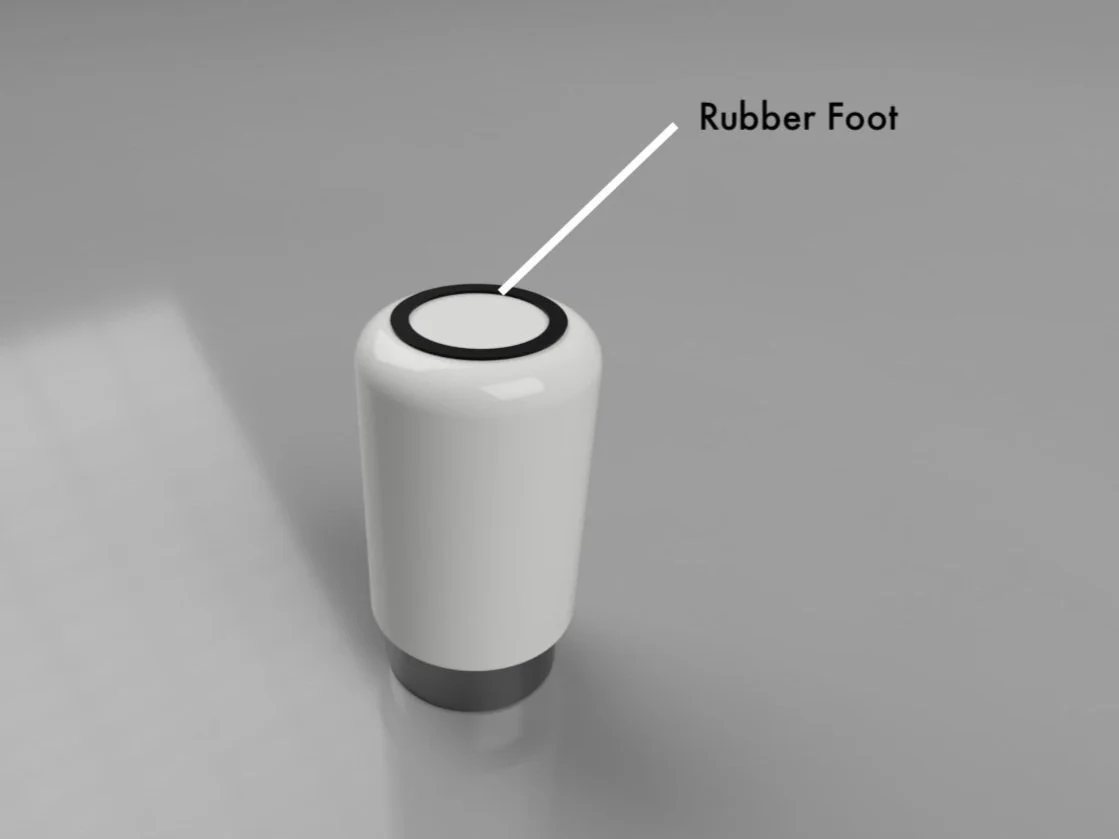

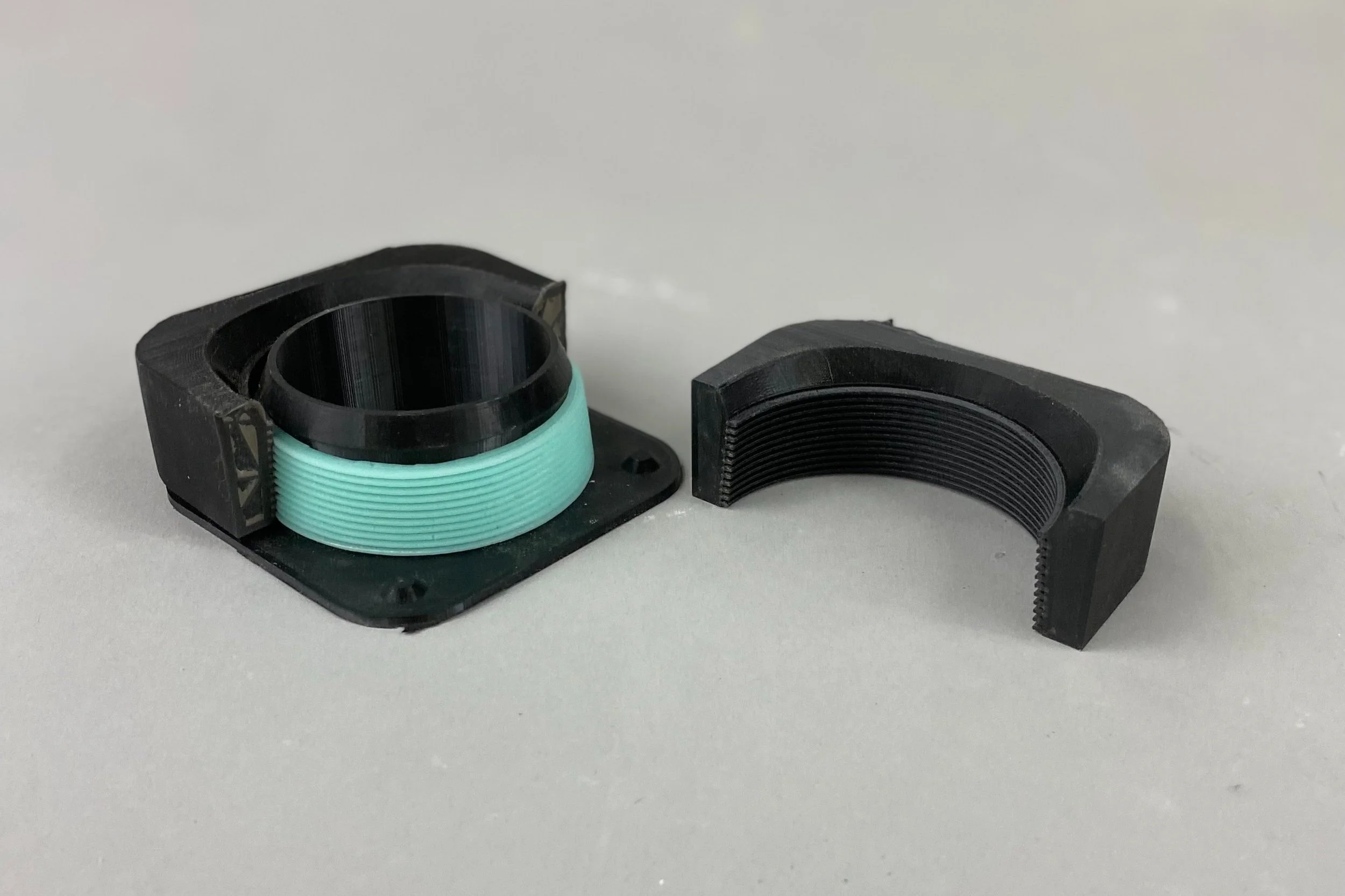

3D Prints

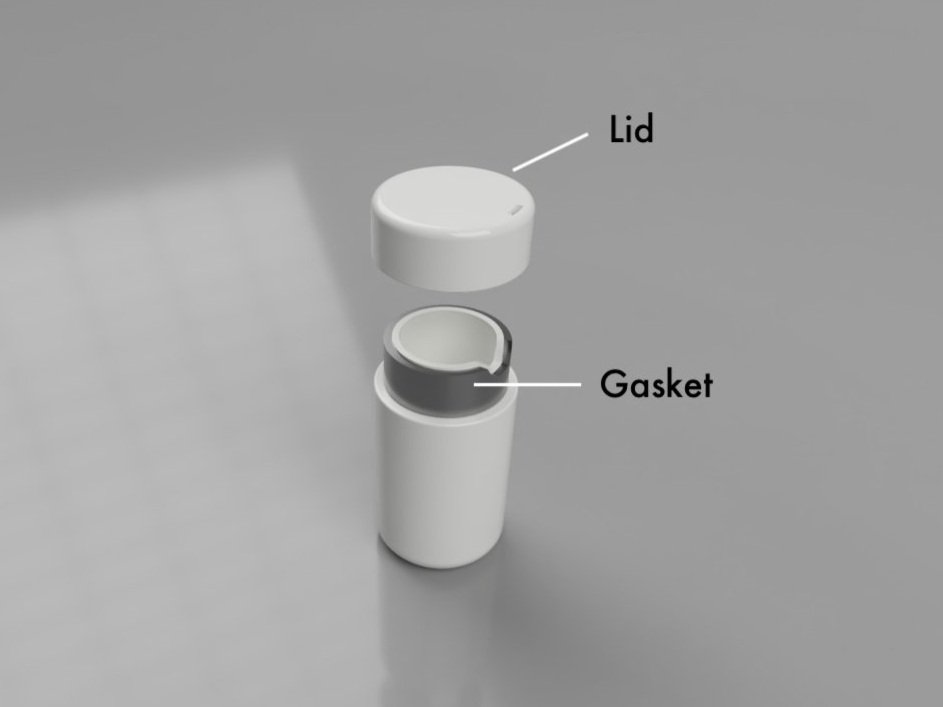

Gasket connected to interior body to provide a water tight seal.

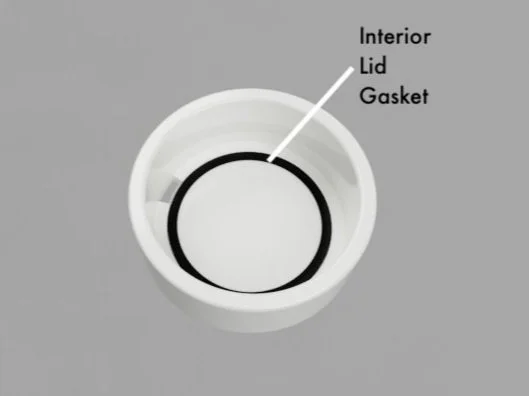

Interior lid gasket, to seal the lip of the vessel to the ceramic lid.

Interior and exterior walls molded separately, this makes the slip casting more reliable.

Rubber foot, for a soft landing on the table.

Once I have a 3D printed model of my design, I hand-make a plaster mold around each component. These molds allow me to cast clay slip into them, giving me a ceramic version of the design. Having ceramic prototypes allows me to further iterate the design, and work through problems that can arise in the casting and firing processes.

Ceramic Prototypes

Concept Iteration 2

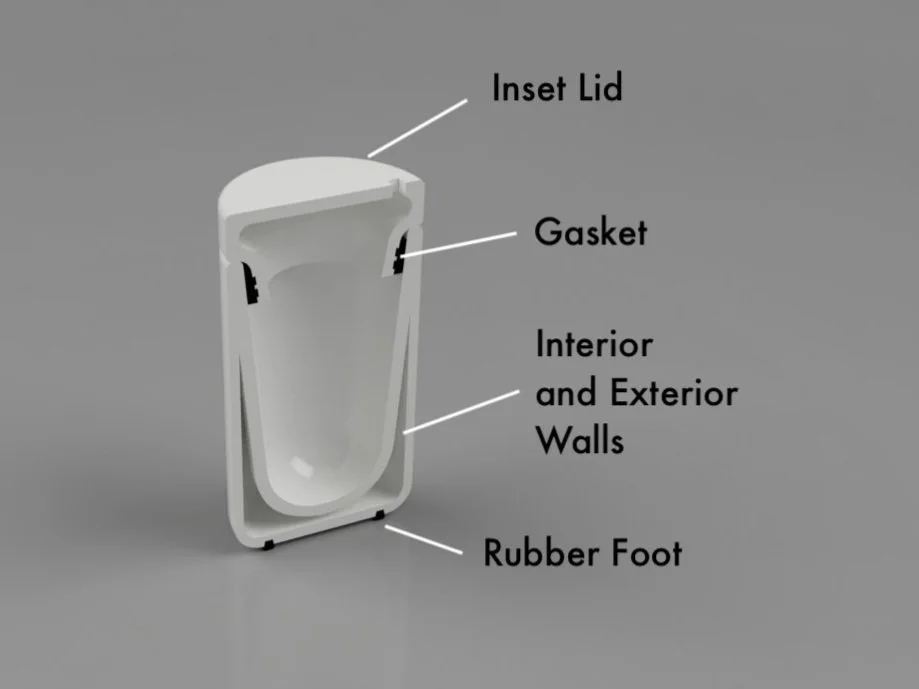

Inset lit

Gasket connected to lid

No interior lid gasket

Rubber foot

Interior and exterior wall molded together

Concept Iteration 3

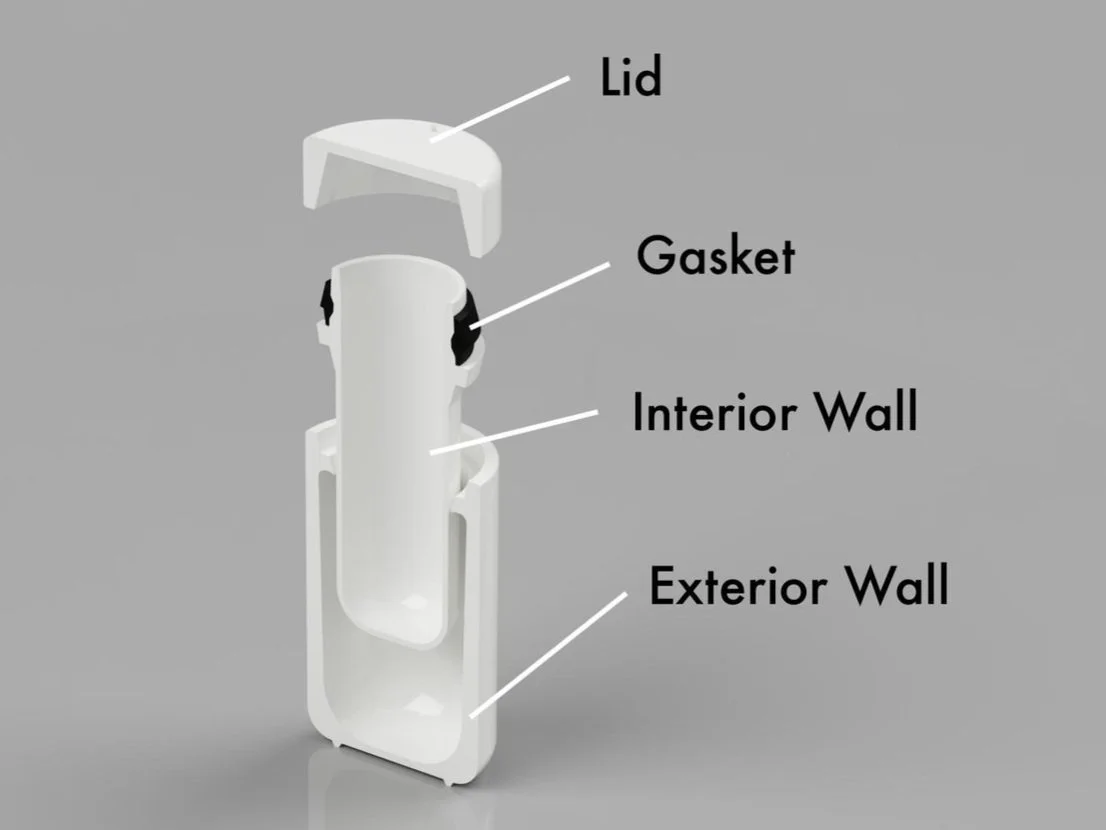

Interior and exterior walls molded separately

Gasket connected to interior body

Ceramic foot, no rubber foot

No interior lid gasket

Master Mold System

Once my design was finalized, I created master molds to increase production efficiency.

Each plaster mold component has its own silicone master mold.

Silicone Gasket Master Mold

Final Prototypes

Expert Advisors

Curt Hammerly

Peter Pincus

Owner of Hammerly Ceramics, Denver Colorado.

Curt specializes in using digital fabrication tools to assist in his mold making practice. He has helped me by giving feedback on the overall design of the object, as well as helping me design silicone master molds, used to generate plaster mold components more efficiently.

Professor of Ceramics at RIT, Rochester New York.

Peter has been my professor and mentor for the last two years. His success in his ceramic career has been due to his innovative and iconic use of plaster molds and the slip casting process. He taught me the mold making process from start to finish, and equipped me with a tool kit of skills I expand on every day.